The maintenance of production plants is of crucial importance for every manufacturing company. To ensure that plants are always in operation and production downtimes are avoided, efficient and [...]

The maintenance of production plants is of crucial importance for every manufacturing company. To ensure that plants are always in operation and production downtimes are avoided, efficient and reliable maintenance is required. The digitalization of maintenance processes offers an enormous opportunity to optimize maintenance work and increase efficiency. A central role in this is played by the Elara app, which should be considered the new standard for the maintenance of production plants. In this article, we will discuss the advantages of Elara as a standard for the maintenance of production plants and show how the use of Elara can revolutionize the maintenance process.

The current state of maintenance in production plants: problems and challenges

However, the current state of maintenance in production plants is often still characterized by manual processes where maintenance work is done on demand and with pen and paper. This can lead to a lack of transparency and monitoring and result in inefficient use of resources. Maintenance tasks may be overlooked or not properly documented, which can lead to errors and unnecessary downtime.

This shows that there is clearly room for improvement. Modern maintenance software like Elara can help companies digitize and automate their maintenance processes. This leads to greater transparency and monitoring of maintenance tasks, more efficient use of resources, and ultimately higher quality and fewer complaints due to a higher quality standard.

There is also the challenge of documentation. Manufacturing companies need to be able to document maintenance activities and monitor the condition of plant and machinery. However, manual documentation is time-consuming and error-prone.

Elara, as a standard for manufacturing plant maintenance, can help overcome these challenges. The Elara app provides an easy way to monitor the condition of plant and machinery and detect problems early.

Documentation of maintenance activities is also facilitated by Elara. The Elara app makes it possible to document maintenance work and repairs and monitor the condition of plant and machinery. As a result, manufacturing companies can not only increase the productivity and availability of their plants, but also improve the quality of their products and reduce the number of complaints.

Overall, Elara as a standard for the maintenance of production plants offers numerous advantages and solutions for the current challenges of maintenance.

Why Elara is suitable as a standard for production plant maintenance: functions and advantages

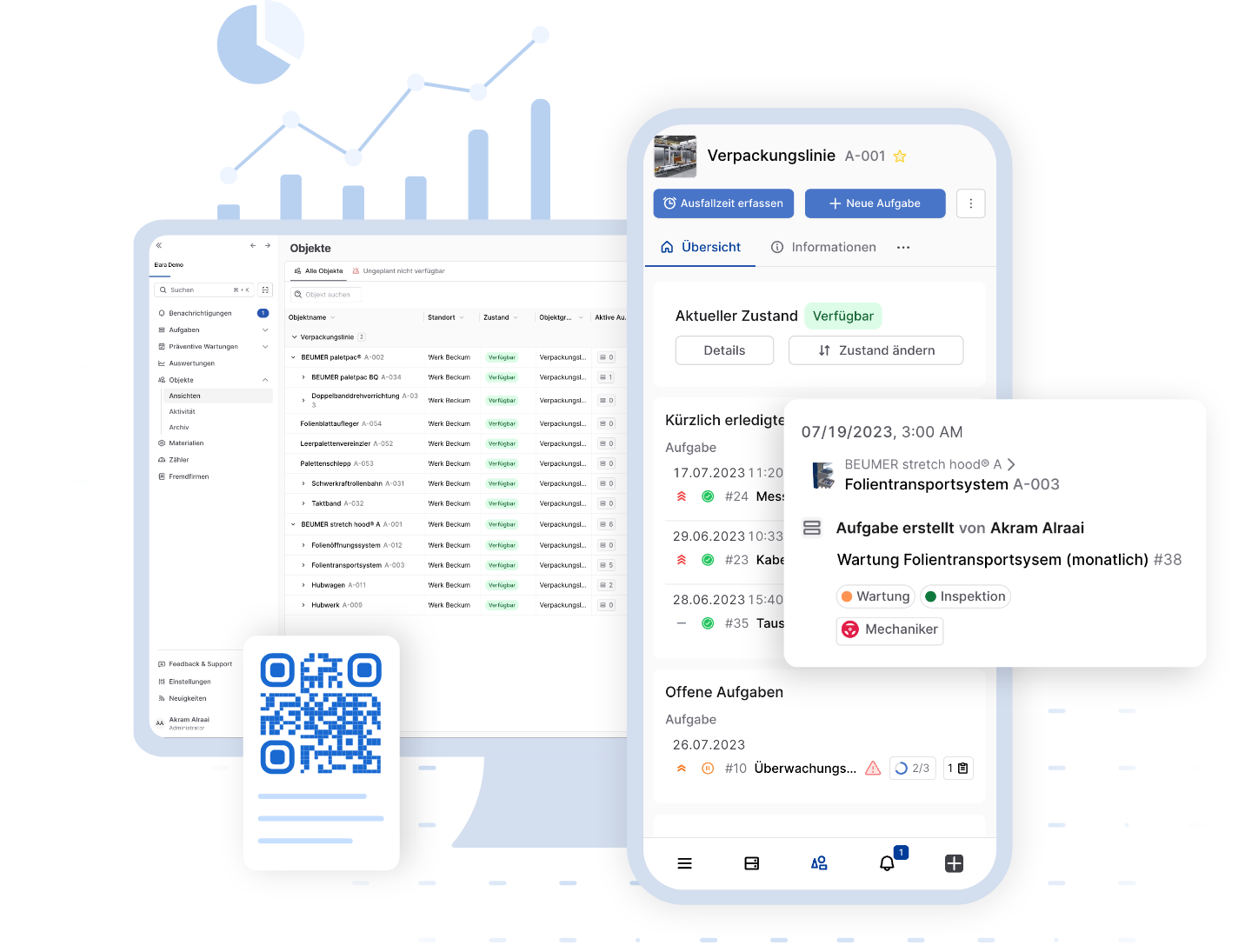

Elara is a maintenance software developed specifically for the needs of manufacturing companies. With a wide range of features and benefits, Elara is the ideal choice to digitize and optimize the maintenance of production facilities.

One of the most important functions of Elara is work order assignment. With this feature, work orders can be created directly in the software and assigned to maintenance personnel. Staff can then track the progress of work in real time and provide feedback to ensure that maintenance is being performed effectively.

Another important feature of Elara is object and asset management. Here, companies can store all relevant information about their plant and machinery, including technical specifications, maintenance requirements and spare parts information. This enables better control and transparency over the condition of the assets and facilitates the planning of maintenance work.

Elara also offers comprehensive spare parts management. Companies can manage spare parts in the software, place orders and monitor stock levels. This feature ensures efficient spare parts supply and minimizes downtime due to missing spare parts.

In addition, Elara also offers meter and value management. This function enables the collection of measurement data and counter readings from plants and machines. Companies can thus track the status of their assets in real time and plan maintenance work accordingly.

Elara’s search function allows users to quickly and easily search for work orders, assets or other information. This saves time and makes it easier to navigate the software.

Another key benefit of Elara is its AI capabilities. This is the first maintenance software that can ask, for example, “what happened in the plant the other day?” or “how did we solve problem XYZ again?”.

In summary, Elara provides a comprehensive maintenance solution for manufacturing companies. With features such as work order assignment, object and asset management, spare parts management, meter and value management, search function and AI functions, Elara is the ideal choice to digitize and optimize the maintenance of production facilities.

Conclusion

Overall, it can be seen that the maintenance of production facilities plays a crucial role in the smooth running of production processes. With modern maintenance software such as Elara, manufacturing companies can digitize and automate their maintenance processes, resulting in higher efficiency, productivity and quality. Elara provides a comprehensive solution for today’s maintenance challenges, from work order assignment and object and asset management to spare parts management and meter and value management. Elara’s AI capabilities make maintenance even smarter and more effective. Overall, Elara as a standard for the maintenance of production plants is a worthwhile investment for manufacturing companies that want to optimize their maintenance processes and sustainably improve their business.

[This is how we create our content.]