Summary of all arguments Improving working conditions through the use of maintenance software Facilitating compliance with audits and certifications through maintenance software Keeping an overview of machines [...]

Inventory managementMachine maintenanceMaintenance management software/CMMSShortage of skilled workersSustainability

Summary of all arguments

- Improving working conditions through the use of maintenance software

- Facilitating compliance with audits and certifications through maintenance software

- Keeping an overview of machines

- Saving time and costs with the proper knowledge at the right time

- Optimising resources and sustainability through spare parts management

- Maintenance software as a solution to skills shortages

- Increasing competitiveness

Who does not know it? As an operation, production, or maintenance manager, you will sooner or later need maintenance software to increase machine plant availability and optimize maintenance processes. After a long search, you finally come across a solution that exceeds your expectations. You go to your supervisor, but he doesn’t want to hear about all this: “We’ll stick to pen and paper or Excel. That’s how we’ve always done it.” If you find yourself doing this, then this article is for you.

Maintenance is an essential part of any business. An effective maintenance strategy is essential to keep plant and machinery in good working order and minimize downtime. In today’s world, many maintenance software systems can help plan and carry out maintenance work. Only a few software solutions meet the requirements of modern applications. But more importantly, how to convince the manager or supervisor that maintenance software is a worthwhile investment.

Five arguments for why now is the right time for maintenance software

More efficiency and cost savings through maintenance software

Maintenance software simplifies work order management, avoids duplication of work, and thus saves time and money. Especially with many machines, plants, and employees, the overview can quickly get lost. Without a practical solution, inefficient working methods lead to wasted time and financial losses.

Optimization of maintenance processes through modern maintenance software

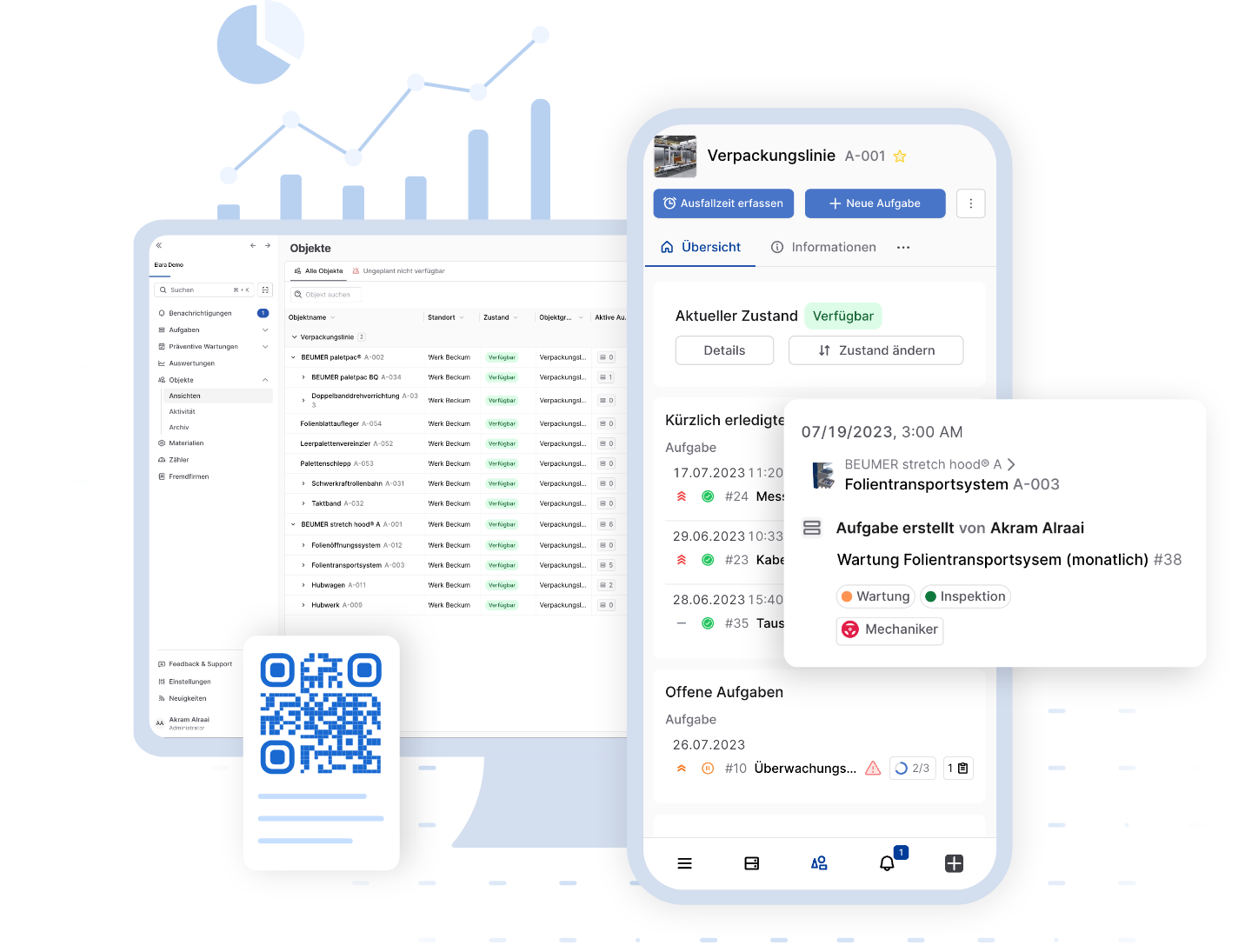

A maintenance solution enables the effective execution of work, repairs, and inspections on machines. Digital work order management facilitates creating and assigning tickets and work orders to individual employees. They are informed immediately by email.

Improved transparency and cooperation in maintenance work through modern maintenance software

Maintenance software allows everyone responsible for maintaining machinery and equipment to access the necessary data and processes. Errors and instructions can be precisely documented in the software to facilitate the work order.

Ensuring compliance with regulations and legal requirements through maintenance software

Maintenance software can ensure compliance with occupational health and safety regulations and legal requirements. For this purpose, important rules and inspection instructions can be stored in the software. Employees always have access to relevant information. In addition, individual maintenance intervals can be set for machines and plants. The software automatically reminds us of upcoming maintenance work to ensure it is carried out.

Optimal monitoring and early detection of defects through modern maintenance software

Maintenance software helps to prevent defects and misunderstandings in the long run. With plant and machine management, your equipment is optimally monitored to detect minor defects at an early stage. Work order management ensures that orders are communicated and assigned to the right employee. With modern maintenance solutions, you never miss repair intervals and keep your machines in optimal condition. This way, minor defects can be quickly remedied.

How to convince your manager or supervisor of a modern maintenance solution

Short-term advantages of a maintenance solution

Improving working conditions

By using maintenance software, work processes can be digitalized and simplified, increasing employee satisfaction. Modern maintenance software integrates various functions, including machine and plant management, inventory, and work order management. Employees can access all critical information on the move and are no longer tied to their desks. A user-friendly software ensures that employees also enjoy working with it. A concrete example is the possibility for employees to create or carry out work orders directly at the machine with the tablet, which saves time and facilitates the daily work routine.

Facilitating compliance with audits and certifications through maintenance software

Through the software, maintenance intervals are automatically recorded, and the responsible employees receive a reminder with the necessary instructions. The maintenance software enables companies to carry out the regular inspection and maintenance of machines and plants more efficiently and precisely, which contributes to the fulfillment of legal requirements and, thus, to the creation of legal certainty.

One example of the audits and certifications that can be simplified by maintenance software is compliant with ISO standards. ISO standards include a variety of standards that a company must meet to be considered certified. With maintenance software, you can more easily demonstrate compliance with these standards by storing all maintenance intervals and logs in the software and retrieving them at the touch of a button. This way, you can ensure that all maintenance work is carried out on time and that no critical dates or protocols are forgotten.

Keeping an overview of your machines

Maintenance software offers companies an easy way to store and manage all necessary information and data in one place. The software captures and stores machine data such as running times and locations, invoices, documents, work orders, photos and videos, which can be accessed at any time. In this way, companies can keep track of their machinery and equipment and ensure effective machinery and equipment management.

Without suitable maintenance software, you have to manage and maintain all information on these machines and assets manually. This includes collecting and managing documents, work orders, maintenance plans, invoices and many other important pieces of information. All this takes a lot of time and can quickly become confusing.

Long-term advantages of a maintenance solution

Resource optimization and sustainability through spare parts management

Spare parts management can help optimise resources and save costs. By carefully managing and monitoring the spare parts inventory, companies can ensure that only the necessary spare parts are kept on hand and unnecessary orders are avoided. This reduces inventory costs and minimises the risk of loss or waste. In addition, well-organised spare parts management can help ensure the availability of spare parts and minimise downtime of machinery and equipment.

Careful management and monitoring of the spare parts inventory not only helps reduce costs, but also reduces waste and thus conserves resources. By avoiding unnecessary orders and effectively using existing resources, the company can reduce its ecological footprint and contribute to sustainability. This not only ensures the availability of spare parts but also minimizes the environmental impact.

Achieving more with the same number of employees – maintenance software as a solution for a shortage of skilled workers

Maintenance software can help to relieve employees and make them work more efficiently. By constantly recording the location of machines and equipment, employees no longer have to search for work equipment, which results in time savings. Work order management also saves a lot of time, as phone calls, emails and conversations can be saved. Overall, maintenance software helps to simplify and speed up processes, which is especially important in times of a shortage of skilled workers.

Nowadays, companies have difficulties finding enough qualified employees for the maintenance of machines and plants. With maintenance software, the company can optimize work processes and use existing employees more effectively. For example, maintenance and repair work can be standardized with the help of checklists and instructions in the software so that employees can work efficiently, even without specific expertise. In addition, maintenance software automatically records maintenance intervals and provides employees with reminders and instructions, saving time and effort and minimizing the risk of errors. This means that less qualified staff can be deployed without compromising the quality of the work.

Increasing competitiveness

Maintenance software can help a company be more competitive in several ways. Firstly, it can help minimize downtime and keep production stable by enabling regular and predictive maintenance. This results in higher customer satisfaction and avoids delays in the supply chain.

On the other hand, companies can save costs and make their prices more competitive by implementing maintenance software. Optimized maintenance ensures a longer life of machinery and equipment, which means less investment in new equipment.

Overall, maintenance software can help a company react more flexibly and quickly to changes in the market. Through greater efficiency and better planning, they can react quickly to new requirements and thus position themselves better against the competition.

[This is how we create our content.]