Effective energy management is essential for companies striving to remain competitive and operate sustainably in today's world. High energy costs and growing environmental responsibilities demand precise monitoring and [...]

Effective energy management is essential for companies striving to remain competitive and operate sustainably in today’s world. High energy costs and growing environmental responsibilities demand precise monitoring and targeted optimization of energy consumption. The right tools are crucial in this endeavor, and an unexpected but highly effective solution is maintenance software.

With the right maintenance software, companies can sustainably and efficiently manage their plant and machinery while significantly reducing energy costs. Although the connection between maintenance software and cost savings might not be immediately apparent—given the initial investment required—the long-term savings can be substantial. By preventing unexpected breakdowns and enhancing maintenance processes through meticulous monitoring of meters and measured values, companies can achieve notable cost reductions. Moreover, energy consumption is directly lowered through the more efficient use of equipment, transforming maintenance from a cost center into a revenue driver.

In this article, we will explore how maintenance software can serve as a pivotal tool for successful energy management and the specific benefits it offers. To illustrate these advantages, we will also present a case study involving a centrifugal pump.

The challenge: keeping an eye on energy costs

High energy costs have been a significant burden on the Eurozone in recent years, creating substantial challenges for companies. These costs often constitute a considerable portion of operational expenses and can heavily impact overall profitability. The primary challenge lies in effectively monitoring and controlling energy consumption, especially for companies with complex production processes and numerous machines. Inefficient processes can result in unnecessarily high energy consumption, significantly increasing operating costs.

Therefore, it is crucial to establish mechanisms for precise analysis and optimization of energy consumption to alleviate financial burdens and enhance environmental sustainability. In some countries, such as Germany, the government is assisting companies in transitioning to energy management software to manage and reduce costs. This support enables companies to set clear energy consumption targets and monitor their progress through metering and measurement systems.

Maintenance software for effective energy management

Unplanned downtime of production facilities is costly and significantly reduces long-term profits. Machine and system failures pose a serious threat to the industrial sector. Recent advancements in Industry 4.0 have optimized maintenance work through new technologies focused on data collection, analysis, interpretation, and application.

Maintenance software is a crucial component of Industry 4.0, utilizing data to maintain systems in optimal condition and identify maintenance needs in advance. This software enables comprehensive monitoring and analysis of systems and machines, allowing for the identification and realization of potential energy savings.

By integrating features such as preventive maintenance and energy consumption data analysis, companies can proactively reduce energy usage and increase equipment efficiency. Additionally, maintenance software facilitates the planning and management of maintenance work, minimizing unplanned downtime and maximizing productivity.

Moreover, improved sustainability through reduced energy consumption not only leads to cost savings but also enhances environmental awareness and the company’s image. By increasing plant availability and reducing downtime, companies can maximize productivity and improve competitiveness.

Implementation of maintenance software for energy management

Unexpected production downtime not only escalates costs but also heightens entrepreneurial risk. Coupled with the increasing pressure of global competition, a shortage of skilled workers, and budget constraints due to high energy prices, companies face significant challenges. However, these challenges also present opportunities.

The comprehensive use of maintenance software can enhance plant reliability, prevent production downtime, and reduce energy costs, ultimately strengthening competitiveness and achieving sustainable cost reductions.

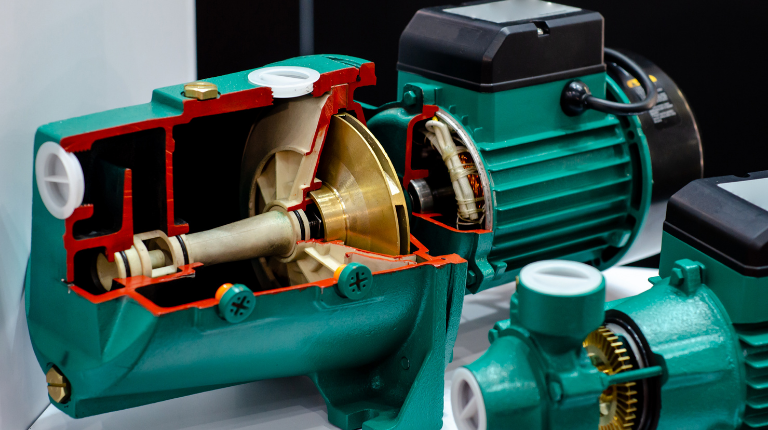

A significant portion of energy consumption in small and medium-sized enterprises is attributed to mechanical systems such as pumps and motors. According to the International Energy Agency, industrial motors account for approximately 70 percent of all electricity usage in industry. Failures and performance declines in motors, belts, or pumps can lead to energy losses. For production companies, motor failures result in costly downtime. Therefore, it is crucial to implement preventive maintenance measures to avoid such failures and ensure continuous, efficient operation.

Reducing energy costs using the centrifugal pump as an example

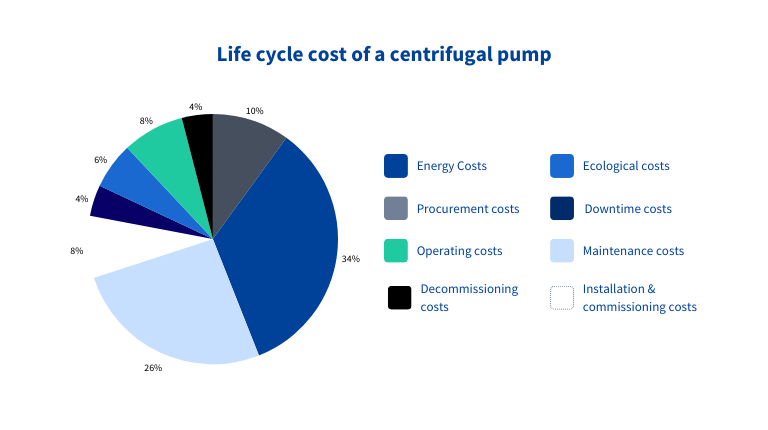

Various pump applications are driven by motors, including centrifugal pumps. When examining the life cycle costs of a centrifugal pump, it quickly becomes evident that energy expenses constitute the largest cost factor throughout its entire life cycle.

According to the Flygt study, energy costs can account for up to 34 percent of the total life cycle cost of a typical wastewater pumping system. The easiest way to reduce energy costs is to identify the Best Efficiency Point (BEP). This indicates the point at which a pump operates most efficiently at a developed head and flow rate. The BEP can be identified by monitoring the meter and measured values. In this way, efficiency can be increased, and energy costs considerably reduced.

An international study found that pumping processes are responsible for around 20 percent of global energy consumption. The better you know your systems and machines, the more feasible it will be to increase productivity within your company and achieve sustainability goals.

How we see energy management at Elara

Based on our experience, maintenance software is a critical tool for companies aiming to reduce energy costs and increase efficiency. Integrating this software into operational processes offers numerous benefits, including preventative maintenance that extends equipment life and minimizes unplanned downtime. By specifically monitoring and analyzing energy consumption, companies can identify and implement potential savings, directly impacting operating costs.

Moreover, effective energy management enhances sustainability, bolsters the company’s image, and supports long-term competitiveness. It is important to note that while the implementation of maintenance software requires an initial investment, it can yield substantial rewards over time. Companies that invest in optimizing their energy management are not only financially rewarded and supported by federal initiatives but also contribute significantly to environmental protection and sustainability.

[In the age of AI, you never know if you’re reading something copy and pasted directly from ChatGPT, or if an actual human sat down to write this with some cool facts from their boss or operations team. That’s why we created a short and simple introduction to how we create content at Elara.]