The implementation of a Computerized Maintenance Management System (CMMS) such as Elara offers numerous advantages for the maintenance of production facilities. Digitization enables seamless collection and management of [...]

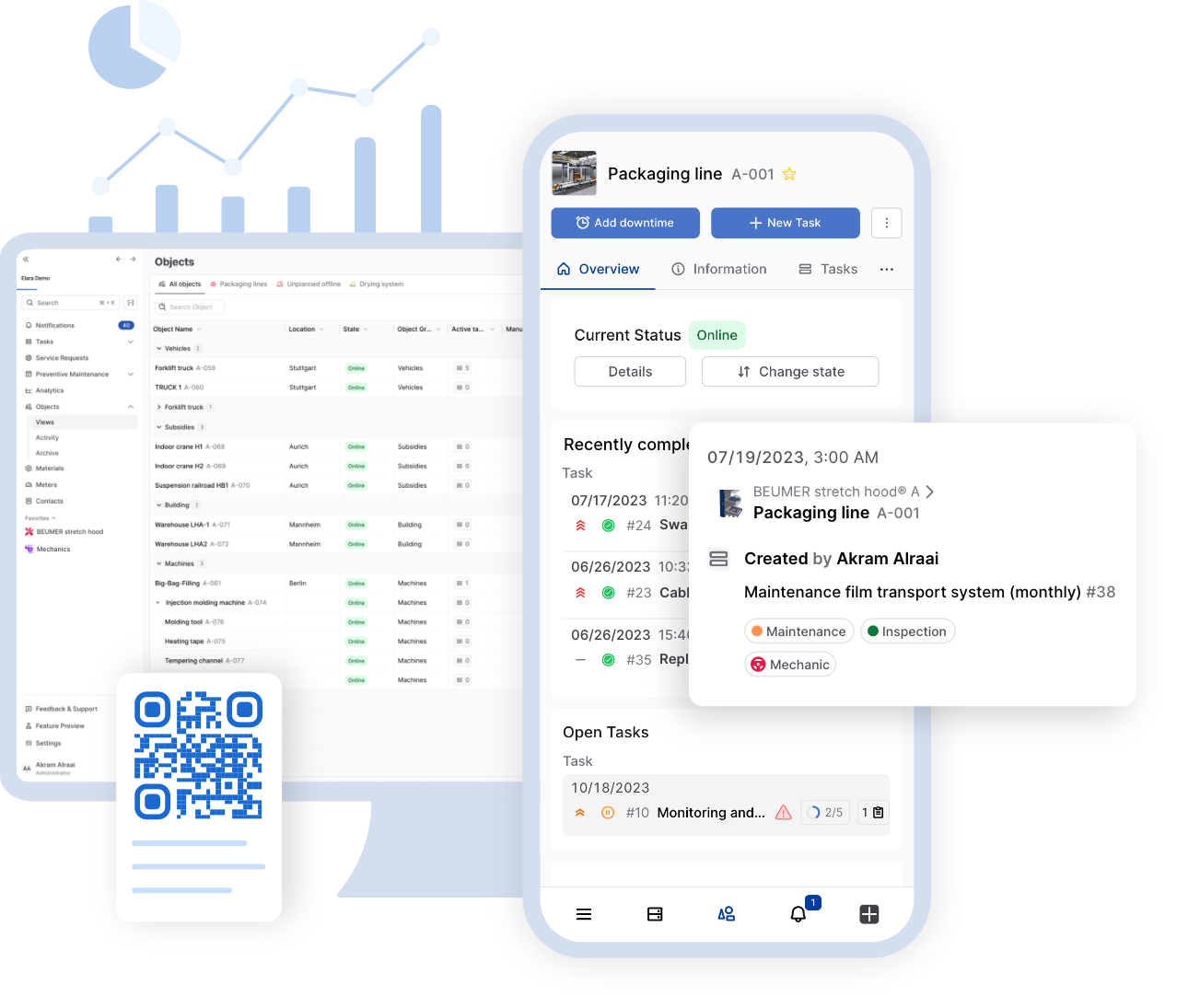

The implementation of a Computerized Maintenance Management System (CMMS) such as Elara offers numerous advantages for the maintenance of production facilities. Digitization enables seamless collection and management of maintenance data, eliminates tedious paperwork, and improves transparency and traceability of maintenance operations.

In this guide, we will highlight the journey from manual processes and paperwork to digitization in maintenance, with a particular focus on the benefits of Elara. We will identify the problems and pains with manual processes, highlight the benefits of digitization, and discuss practical steps to implement a CMMS for more efficient maintenance.

Prepare to be in a maintenance environment no longer dominated by tedious paperwork, illegible notes, and inefficient processes. Let’s walk the path of increased efficiency in maintenance together and find out how Elara as a standard CMMS can help revolutionize maintenance.

Problems and Pains with Manual Processes and Paperwork

Maintaining plant and machinery is a complex task that comes with many challenges. However, when manual processes and paperwork are involved, additional problems and pains can arise that affect the efficiency and productivity of maintenance operations.

Waste of time and resources

Manual processes require a lot of time and effort. From creating work orders to documenting maintenance tasks to communicating between maintenance teams and other departments, each task requires manual intervention and handling of paper documents. This leads to inefficient use of resources and delayed maintenance activities.

Proneness to error

Manual processes are at higher risk for errors and inaccuracies. Paper documents can be lost, illegible, or misinterpreted. These errors can lead to mistakes in performing maintenance or failure to record important information. This, in turn, can lead to unforeseen outages, extended downtime, and even safety risks.

Lack of visibility and traceability

Manual processes make it difficult to accurately track the status and progress of maintenance work. Information can be scattered, and it’s tedious to track the progress of tasks, assigned resources and completed work. This leads to a lack of visibility and makes it difficult to plan maintenance work in a timely manner and identify bottlenecks.

Knowledge loss

Paper documents are susceptible to damage, loss or lack of archiving. This can lead to a significant loss of knowledge as important information about maintenance work, machine history and best practices is lost. New employees must painstakingly search for information or rely on oral traditions, which can lead to inconsistencies and uncertainty.

These problems and gains in manual processes and paperwork underscore the urgent need to digitize and automate maintenance processes. By overcoming these obstacles, organizations can increase maintenance efficiency, improve productivity, and reduce the risk of downtime and safety issues. In our further guide, we will show how Elara, as a leading CMMS system, provides a solution to these problems and paves the way to a digitized future of maintenance.

Advantages of digitization in maintenance

The digitization of maintenance processes offers numerous advantages and opportunities for manufacturing companies. By using modern CMMS systems like Elara, companies can free their maintenance from manual processes and paperwork and significantly increase the efficiency of their operations. Here are some of the key benefits of digitization in maintenance:

Time and cost savings.

By automating maintenance processes, companies can realize significant time and cost savings. Work orders can be easily created and assigned, communication between teams is simplified, and tracking tasks and progress becomes more efficient. Reduced reliance on paper documents saves time on documentation and enables faster access to critical information.

Improved transparency and traceability

By digitizing maintenance processes, greater transparency and traceability is achieved. All relevant information is stored centrally in a CMMS system and is accessible to all parties involved. This enables better planning of maintenance work, optimized resource allocation and accurate monitoring of the progress of maintenance measures.

More effective use of resources

Digitization enables more effective use of resources in maintenance. By optimizing the scheduling of maintenance work, companies can ensure that the right people are working on the right tasks at the right time. This minimizes downtime, reduces costs and maximizes the efficiency of maintenance operations.

Improved data analysis and reporting

With a digital CMMS system like Elara, companies can collect comprehensive data about their maintenance activities. This data can be analyzed to identify trends and patterns, predict potential bottlenecks, and optimize asset performance. In addition, digital reporting enables detailed analysis of maintenance performance and identification of areas for improvement.

Better inventory management

By digitizing maintenance, companies can improve their spare parts and inventory management. A CMMS system enables accurate tracking of spare parts, orders and inventory movements. This ensures that the right spare parts are available at the right time to minimize downtime and maximize maintenance efficiency.

To make the most of the benefits of digitization in maintenance, companies should develop a holistic strategy. This includes selecting a suitable CMMS system such as Elara that meets the company’s individual requirements and needs. It is also important to prepare employees for the changes and provide training to ensure they can use the new system effectively.

Digitization in maintenance is a continuous process that requires constant adjustments and improvements. Companies should regularly analyze their processes and performance to identify potential areas for optimization. Through continuous improvement and innovation, companies can further increase their efficiency in maintenance and sustainably achieve their goals.

Overall, the digitization of maintenance offers numerous benefits, ranging from time and cost savings to improved transparency and traceability, effective resource utilization, better data analysis and reporting, and improved inventory management. By using a CMMS system like Elara, companies can move away from manual processes and paperwork to the efficient and sustainable digitization of maintenance.

[In the age of AI, you never know if you’re reading something copy and pasted directly from ChatGPT, or if an actual human sat down to write this with some cool facts from their boss or operations team. That’s why we created a short and simple introduction to how we create content at Elara.]