Machine and equipment maintenance is essential for manufacturing companies to maintain uninterrupted production and meet quality standards. Maintenance encompasses all actions that maintain the operational functionality of machinery [...]

Machine and equipment maintenance is essential for manufacturing companies to maintain uninterrupted production and meet quality standards. Maintenance encompasses all actions that maintain the operational functionality of machinery and equipment. In recent years, maintenance management has actually started to change significantly. The creation of modern maintenance software has played a key role in enabling manufacturers to streamline their maintenance routines and reduce costs.

While traditional maintenance systems often struggle to meet the demands of today’s connected manufacturing environments, cloud-based maintenance software solutions have introduced a new era in the industry through the integration of IoT (Internet of Things) and cloud software. Often referred to as Software as a Service (SaaS), these cloud-based applications run over the internet rather than on local computers or servers. This innovative approach allows manufacturing companies to manage, monitor, and control their equipment flexibly, scalably, and in real-time online.

In this article, we will look at the benefits of such a cloud solution for manufacturing companies, and how they can benefit from using cloud-based maintenance software.

The challenges of traditional maintenance systems

Traditional maintenance systems face a number of challenges that significantly impact business efficiency and performance. These legacy systems typically rely on locally installed software, which may seem adequate at first, but eventually become limited in both scalability and flexibility. These limitations make it difficult to extend and standardize maintenance processes across multiple sites or facilities, often resulting in inconsistent operations.

Furthermore, the integration of legacy systems with other operational software applications is often problematic. This can lead to data inconsistencies and inefficient workflows as information is not seamlessly shared between different systems.

Another obstacle is manual data entry, which can create a bureaucratic paper trail. This outdated practice not only slows down processes but also results in a lack of real-time information, making predictive maintenance difficult and leading to unplanned downtime and production interruptions.

Overall, traditional maintenance systems are outdated and cannot meet the demands of a modern, digitalized production environment. Companies that want to remain competitive must implement new, innovative solutions to optimize their maintenance processes and improve their operations.The solution to these challenges lies in the implementation of modern, digital maintenance systems. These provide a scalable and flexible platform that allows for a smooth integration with other operational applications and delivers real-time information to support preventive maintenance and minimize downtime.

What is cloud-based maintenance software?

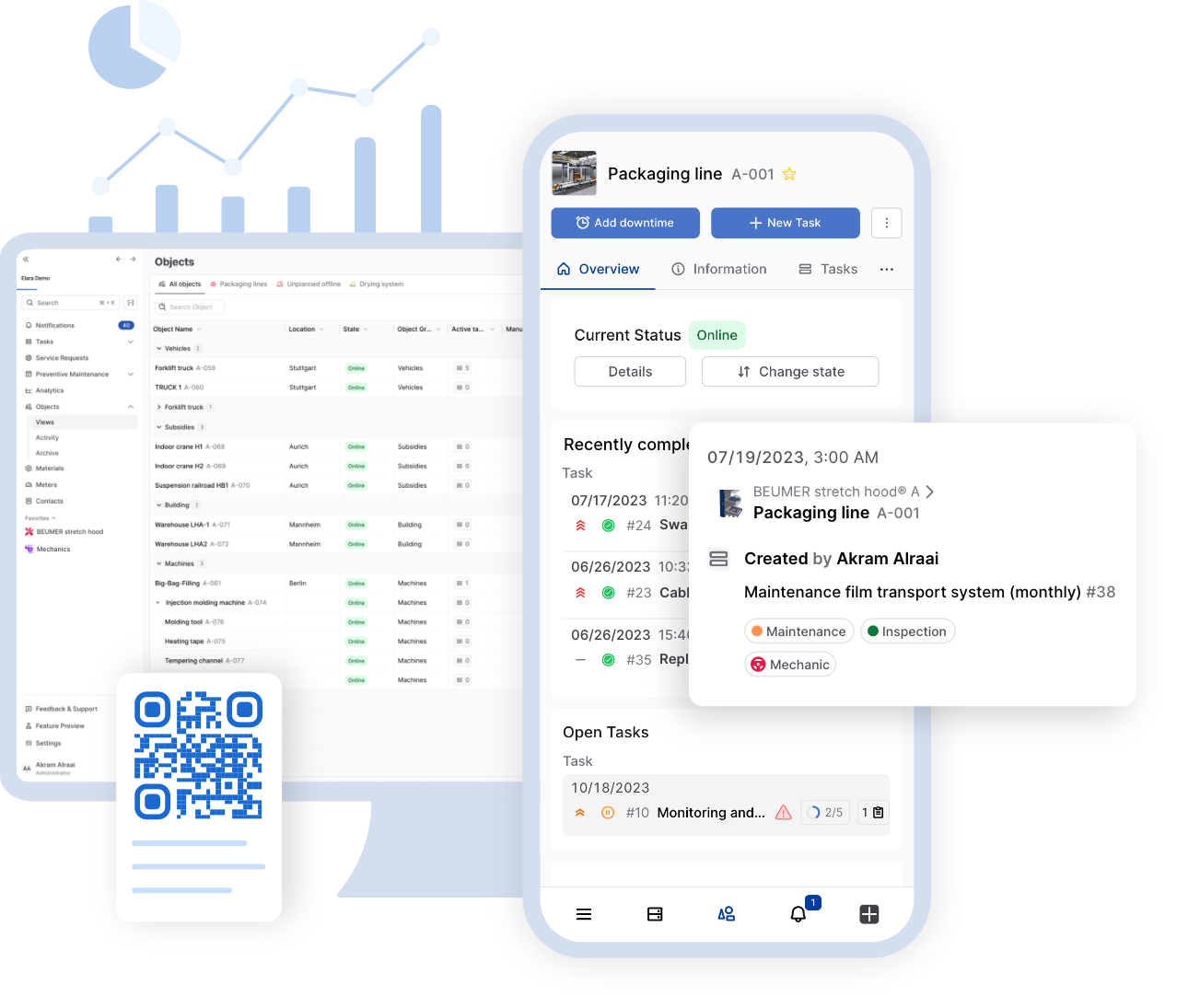

Cloud-based maintenance software is a modern solution which enables manufacturing companies to improve the efficiency and effectiveness of their maintenance processes through the use of cloud technology. Unlike traditional on-premises systems, cloud-based maintenance software is delivered and managed over the internet. This means that the software does not need to be installed on the company’s local servers. Instead, it is hosted and maintained by an external provider. This cloud-based delivery gives manufacturers the advantage of being able to access the software anytime, anywhere, as long as there is an internet connection. In addition, a cloud-based solution is highly scalable. Resources can be quickly and easily adjusted as needed.

Integrating the Internet of Things (IoT) into cloud-based maintenance software also enables the ability to seamlessly collect and analyze real-time data from production equipment, enabling more accurate monitoring and proactive maintenance. Ultimately, cloud-based maintenance software provides a flexible, cost-effective and future-proof solution for manufacturing companies looking to streamline their maintenance processes. Companies can also benefit from regular automatic updates and maintenance without disrupting operations. This minimizes downtime and ensures that the software is always up to date to meet ever-changing requirements and technologies.

The benefits of cloud-based maintenance software for manufacturing companies

The advantage of cloud software over on-premises solutions is that there is no need for additional IT infrastructure such as servers and support. As a result, software deployment can be fast and easy. All that is required for access to the software are end devices such as workstations, smartphone, or tablets, which are usually already available. What’s more, cloud software can be accessed from anywhere, anytime. This is especially important in an era of telecommuting to stay in touch with colleagues and teams and collaborate effectively.

Another advantage of cloud-based maintenance software is that the software is always up-to-date and automatically updated. This eliminates the time-consuming process of updating that often comes with local solutions. The flexibility of cloud-based maintenance software also means that organizations only pay for what is needed. This saves money and frees up resources to focus on other important issues. Businesses can also quickly and easily scale up or down the number of licenses on demand while making it easier and faster to integrate new applications and features.

Overall, cloud-based maintenance software offers greater flexibility and scalability. It is also more cost-effective in the long run. And it offers greater data security. Consider the benefits of cloud maintenance software and optimize your maintenance processes.

Which companies can benefit from maintenance software?

A common argument against the implementation of maintenance software is the question of whether maintenance software is really necessary for every manufacturing company. For very small companies with only a few machines and one or a few people dedicated to maintenance, using maintenance software may be overkill. However, the benefits of maintenance software can be made available to smaller companies through cloud technology. Another benefit for smaller companies is that they get to try before they buy. Cloud-based maintenance software requires no additional IT infrastructure and can be purchased with fewer features to save money. This means that even small companies can take advantage of the benefits that maintenance software can offer and streamline their maintenance processes.

Maintenance processes are not only limited to companies in the manufacturing industry, but are also of great importance in other industries such as logistics, construction, building services engineering and health care. Maintenance and repair of transportation, buildings or medical equipment is often required in these industries. By using maintenance software, maintenance processes can be optimized in these industries as well.

Implementing maintenance software can also help improve efficiency, safety, and optimize costs. Companies in these industries can also enjoy the benefits of technology and take their maintenance processes to a new level by using cloud software.

The benefits of cloud maintenance software from Elara’s perspective

At Elara, we know that maintenance software is not only an issue for manufacturing companies. It’s also needed in many other industries, such as logistics. In these industries, too, the implementation of maintenance software results in process optimization, efficiency and profitability.

By eliminating the need for additional IT infrastructure and allowing companies to pay only for the functionality they need, maintenance software in the cloud offers benefits such as flexibility, scalability and cost efficiency. It also ensures a high level of security and timeliness through automated updates and constant availability of the software.

Although the implementation of maintenance software for very small businesses may be overkill in some cases, many smaller businesses can benefit from cloud technology and test the software to see if it meets their needs and helps their employees work.

The use of maintenance software is about more than just the prevention of downtime. It gives maintenance teams the opportunity to make a significant contribution to the bottom line and to optimize operations for the long term. Elara makes it easier for maintenance teams to move from a reactive maintenance strategy to a proactive maintenance strategy. In addition, Elara’s advanced maintenance software provides capabilities for resource planning, inventory management, and documentation of maintenance activities that allow for the efficient use of resources and improved visibility. As a result, implementing maintenance software not only lowers costs and improves efficiency, but also enhances competitiveness and customer satisfaction.

For many companies, maintenance software is an important tool to help them streamline their maintenance processes and avoid costly downtime and expenses. However, companies should always carefully consider which type of maintenance software best suits their needs. They should also continually evaluate and adapt the software to achieve the best results.

[In the age of AI, you never know if you’re reading something copy and pasted directly from ChatGPT, or if an actual human sat down to write this with some cool facts from their boss or operations team. That’s why we created a short and simple introduction to how we create content at Elara.]