- 🔥 New: Download Whitepaper now!

- 📢 Go to Resources/Downloads

Cloud Software from Germany for SMEs Worldwide:

The way to a better future for maintenance optimization

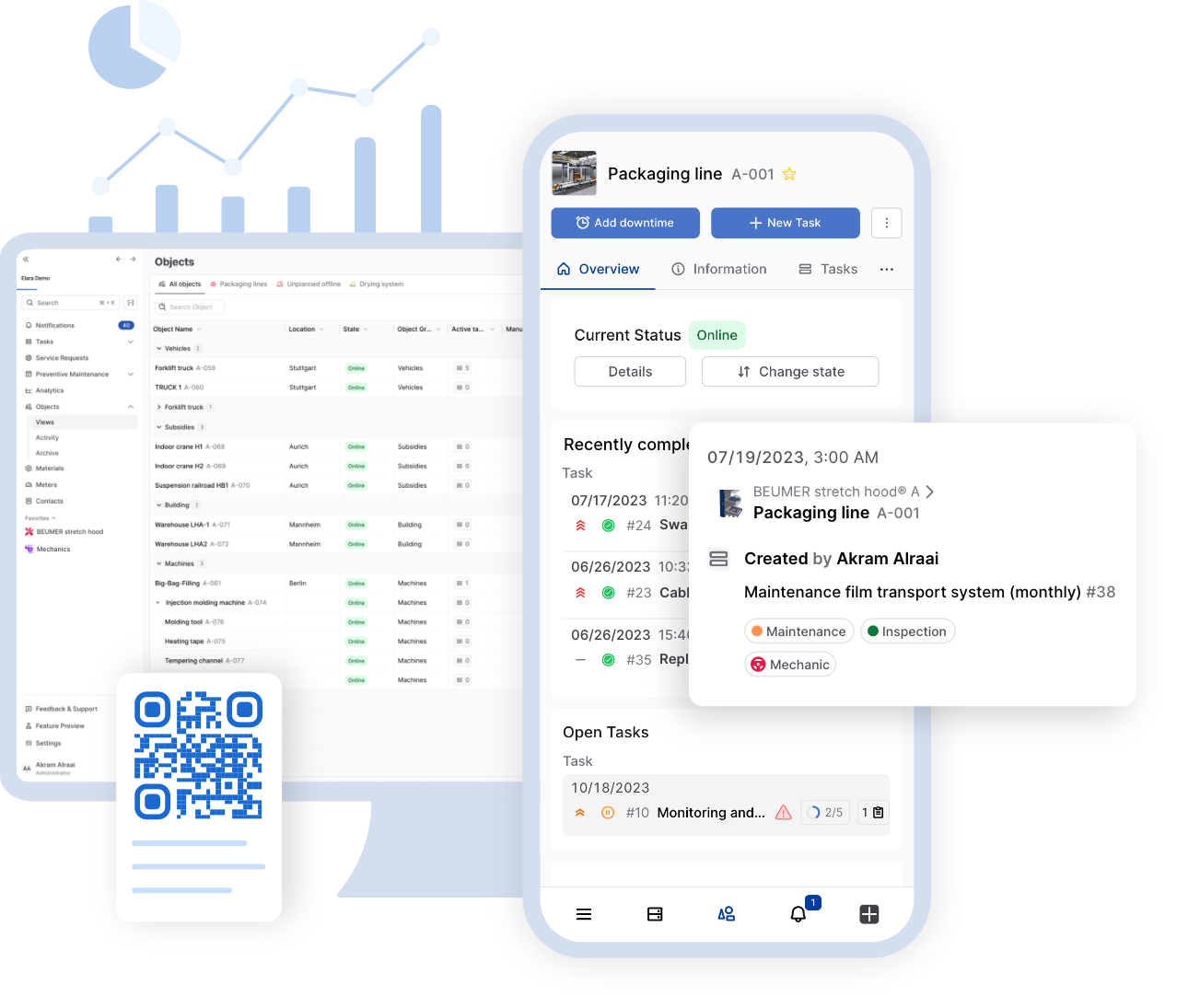

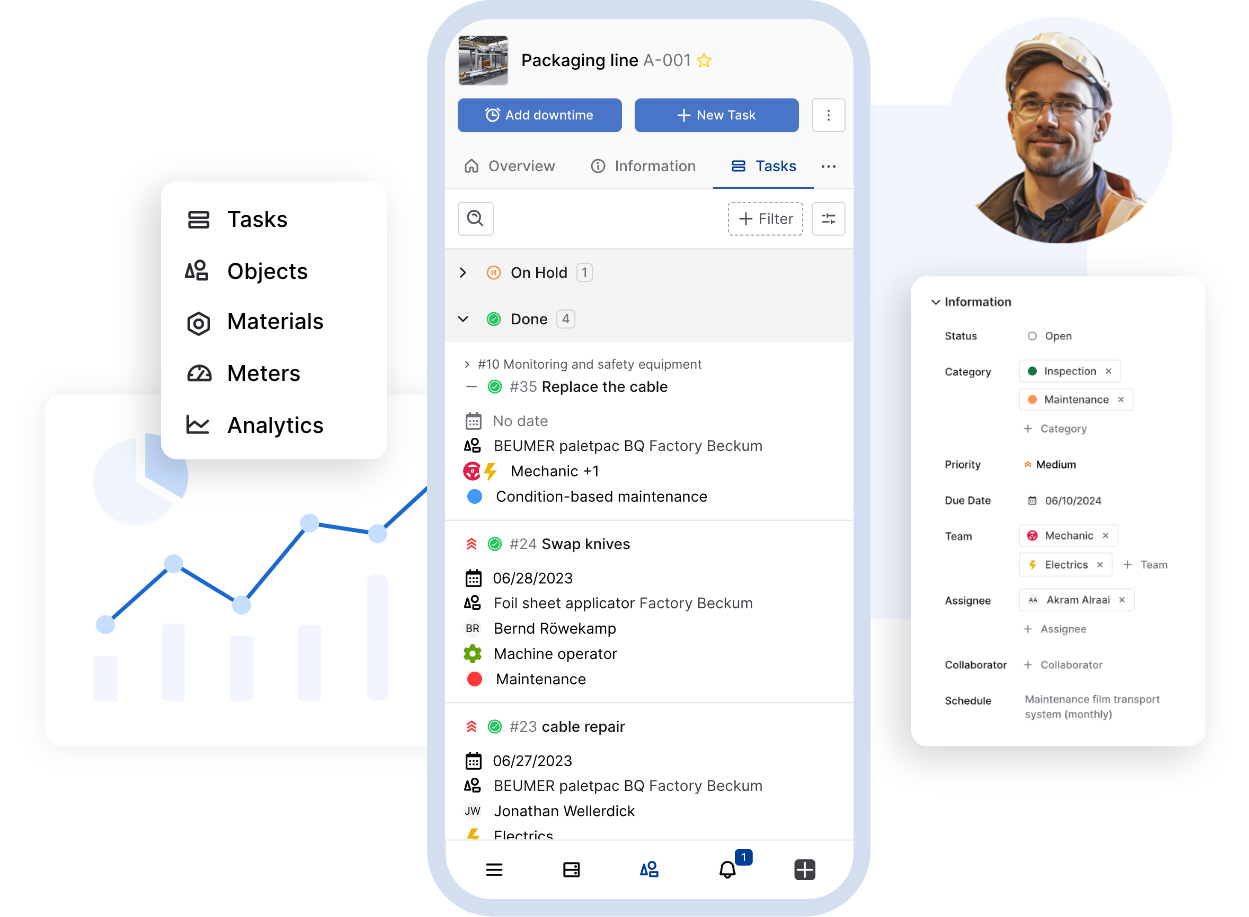

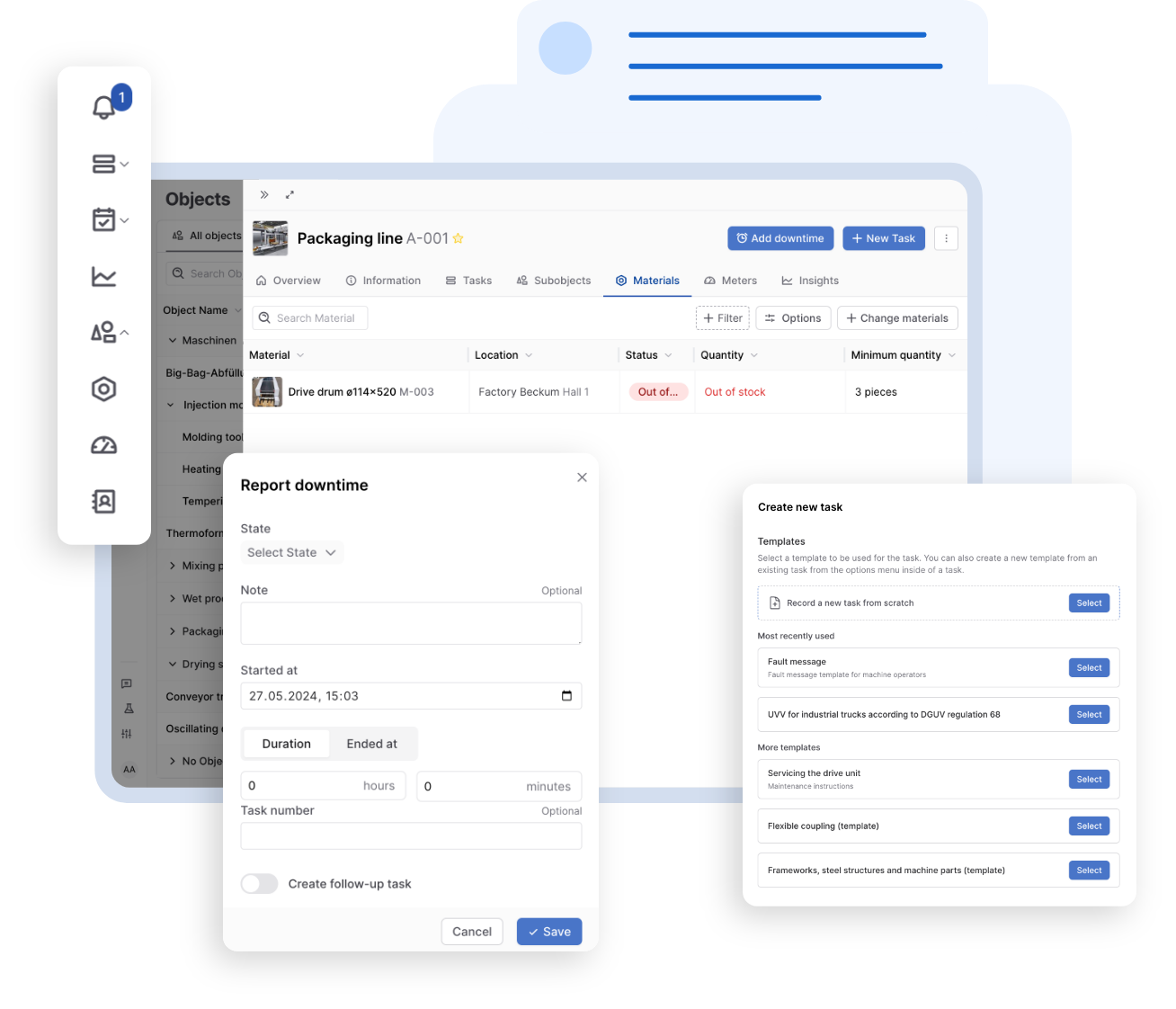

The data of your plants, spare parts and equipment do not belong in a silo. Elara centralizes everything in one place and allows it to be accessed from anywhere. That means less guesswork and more time to focus on what’s important.

Access to all equipment and resources from anywhere

With Elara, you can record and manage all the important objects for your business clearly in one place. Whether machines, vehicles, buildings, equipment, tools or spare parts. All documentation (whether manuals, circuit diagrams, invoices or inspection records) can be retrieved quickly and easily in one place.

Recurring tasks and preventive measures – Easy to track

Record all regular tasks such as maintenance and inspections. Thanks to automated reminders, you can make all preparations so that the tasks are completed on time. Regular tasks based on operational values such as operating hours are also no problem.

What customers say about our Maintenance software

Elara simplifies internal communication immensely. Everything you need to know is in your pocket, so less is forgotten and deadlines are met.

Since we started using Elara, we have less paperwork and nothing is forgotten.

Thanks to Elara, we can track what mistakes have been made in the past and get away from the tedious paperwork.

Elara facilitates monitoring and coordination. In addition, all activities with operational objects can be documented in detail.

Elara allows us to track who did what and when. This makes all processes in general more transparent and we no longer have to create Excel spreadsheets for every little thing.

If there are breakdowns, we have introduced processes with Elara so that replacements can step in and operate a plant. In addition, we now have a central database and no more scattered data on maintenance, spare parts, etc.

Notes lying around, Excel lists, confusion; Elara got a handle on all of that for us.

Elara solves problems for us that accumulated in the past primarily in the areas of organization, management of objects and clarity. Now we have everything brought together in one place.

Maintenance of all kinds, as well as work on machines, can be perfectly organized by Elara.

The organization of work through Elara facilitates a lot and through the logbook it is also possible to track what work was done in the past, when and by whom.

Thanks to Elara’s clarity, operational orders are processed in full and tasks relating to production can be created and processed down to the last detail.

The general technical condition of our facilities has improved since we started using Elara. No more maintenance or the like is forgotten because communication is facilitated.

Pricing

Scalable Maintenance Software with Unlimited Users and Storage