The topic of sustainability is becoming increasingly relevant in all areas of life. From material procurement at the supplier to the production process in the small manufacturing company [...]

The topic of sustainability is becoming increasingly relevant in all areas of life. From material procurement at the supplier to the production process in the small manufacturing company to waste management in the industrial group – the economy in resource and energy consumption is moving higher and higher up the list of priorities. They all have one thing in common: well-functioning machines and perfectly planned processes are the be-all and end-all. And this is precisely where sustainable use plays an important role.

Why is sustainable machine use so important?

In production, every mistake costs: machine downtime, wasted working time, and wasted resources; the list is long. And it is easy for this to happen because sustainable machine use requires routine tasks on the individual components. These routine tasks include but are not limited to regular inspections, lubrication, cleaning and maintenance, replacement of worn parts, and checking and calibration of measuring and control devices. However, these important tasks are easily forgotten, and the more carelessly manufacturing companies handle this issue, the more frequently unplanned downtimes occur. Consistently performing these tasks ensures the efficiency and reliability of machinery assets, leading to longer life, less downtime, and reduced maintenance costs.

Why is the sustainable machine use worthwhile?

When machines are used more sustainably and thus more consciously, there are fewer malfunctions and breakdowns, lower repair costs, less downtime, and less waste of raw materials. An example of this is bearings, which have a longer service life due to regular maintenance and lubrication and thus need to be replaced less often. This leads to a reduction in maintenance costs and higher plant availability.

Another example seals, which also benefit from sustainable use. Regular inspection and timely replacement of worn seals can prevent leaks and damage to machine components. This helps to extend the life of the machine and avoid costly repairs.

In addition, sustainable use of machinery extends the entire plant’s life, improves resource and work planning, and increases occupational safety. In short, sustainable use of machinery means saving money, and time and longer service life.

How can I use my machines more sustainably?

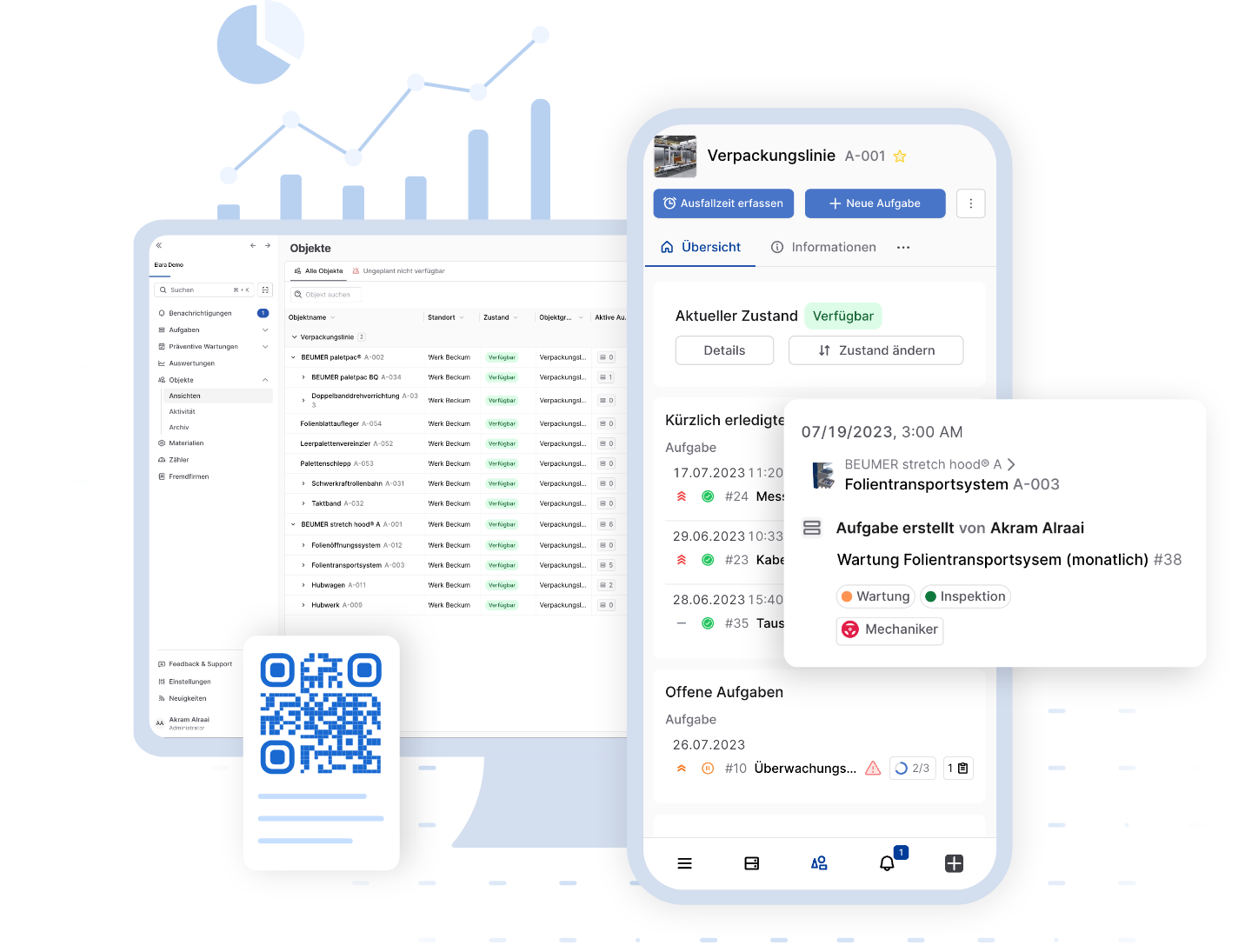

How can I use my machines more sustainably? All this can be achieved, for example, through maintenance software such as Elara. With innovative software like Elara, which manufacturing companies and the production industry increasingly use, you always get an overview of all tasks, and recurring tasks can be better planned. An interactive checklist with concrete work steps can help to optimize the maintenance process and avoid mistakes when handling the machine. An example of such a checklist could look like this:

- Inspection of the machine and its components for wear or damage.

- Checking the lubrication points and topping up the lubricant if necessary.

- Cleaning the machine and work area to remove dust and dirt.

- Checking and replacing worn parts, such as bearings or seals

- Checking and calibrating measuring and control devices to ensure the correct functioning

- Documentation of the work carried out and setting of the next maintenance date

A checklist ensures that nothing is forgotten because it is a systematic tool that presents all relevant steps and tasks within the scope of machine maintenance and servicing. This means that avoidable errors no longer occur. In this way, the maintenance software contributes significantly to the sustainable use of machines.

Digitizing and passing on knowledge

But the software is also useful for other challenges. It makes it possible to easily digitize the knowledge of skilled workers and pass it on to successors, trainees, career changers or short-time workers simply and practically. Other challenges include:

Shortage of skilled workers: In many industries and companies, there is a shortage of qualified workers. With maintenance software like Elara, the existing knowledge of experts can be digitised and made easily accessible to make it easier for new employees and career changers to get started and maintain the quality of work.

Adaptability to change: In a constantly changing production landscape, companies must remain flexible and adaptable. Maintenance software makes it possible to react quickly to changes in production processes or the machines themselves by providing all the necessary information for maintenance and adapting the maintenance process to changing conditions.

Compliance with legal regulations and standards: In many industries, some strict legal regulations and standards must be adhered to when maintaining machinery. Maintenance software such as Elara helps companies ensure compliance with these regulations by centrally managing all relevant information and documents and making them available when needed.

Here, too, resources in the form of personnel, time, and costs are saved, and work quality and safety are significantly increased. Maintenance software helps companies to meet these challenges effectively and to make their production processes more sustainable and efficient.

Is it worth it?

The future is becoming increasingly digital, raw materials are becoming scarcer, and the world of work is changing. Keeping up with the times has never been more important. Software like Elara makes it possible to be at the forefront of all these issues, become more sustainable, reduce costs, and increase quality simultaneously. Over 100 companies are already benefiting from Elara, making an additional positive contribution to securing our future.

Seize the opportunity to increase sustainability and efficiency

Don’t miss your chance to discover in which areas Elara can increase sustainability and efficiency in your company and avoid unnecessary costs. Book a 30-minute product demo with our Managing Director, Akram Alraai, now: https://getelara.de/kontakt/

The benefits of sustainable use of machinery assets are clear: increased efficiency, reduced costs, and longer machine life. With the right software, like Elara, you are well-equipped to take this important step toward sustainability and efficiency. Don’t wait any longer and discover how Elara can benefit your business.

[This is how we create our content.]