What is cloud software in maintenance and how can it help manufacturing companies? Maintenance of machinery and equipment is a crucial factor for manufacturing companies to ensure smooth [...]

What is cloud software in maintenance and how can it help manufacturing companies?

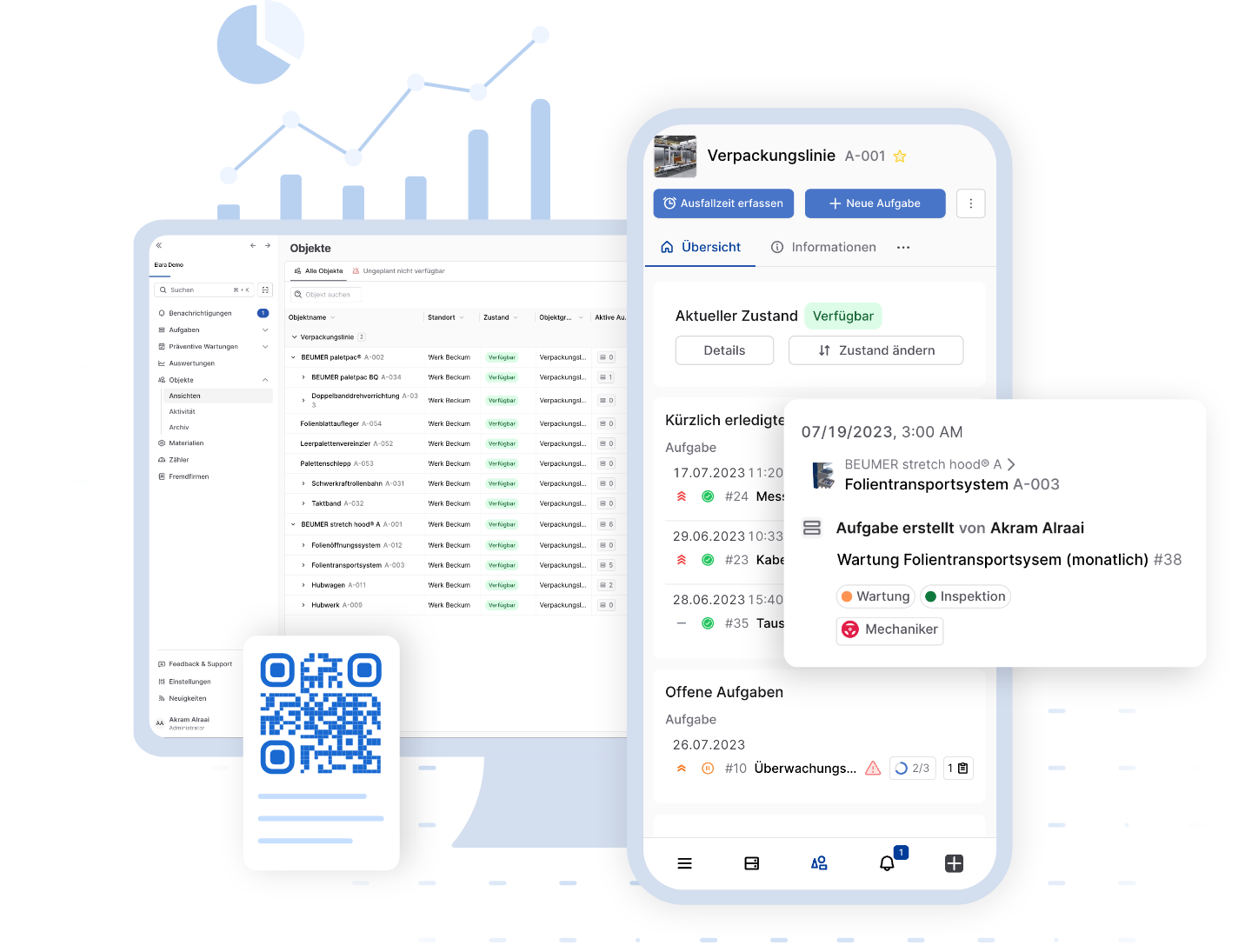

Maintenance of machinery and equipment is a crucial factor for manufacturing companies to ensure smooth production and compliance with quality standards. However, maintenance management has changed drastically in recent years. Modern maintenance software has become increasingly important in this context, as it can help manufacturing companies to optimise their maintenance processes and save costs. Many manufacturing companies are not familiar with the benefits of cloud software. In this article, we will take a closer look at how cloud software can help manufacturing companies improve their maintenance processes and optimise production processes. We will discuss the benefits of cloud software in maintenance and highlight the requirements for manufacturing companies.

From challenge to opportunity: How cloud software can solve problems in maintenance

Implementing preventive maintenance plans is a challenge for many manufacturing companies. Maintenance software can help companies overcome this challenge and turn it into an opportunity to become more modern and implement the latest technologies.

Maintenance software helps companies monitor the condition of their machines and predict when maintenance is needed, rather than just reacting to failures. Implementing preventive maintenance plans requires a thorough analysis of machine data to find out what maintenance is needed and when it should be done. For example, the interval for a V-belt change can be found out based on the documented operating hours of a machine. Then, with the help of maintenance software, a maintenance schedule can be created and documented in the software.

However, cloud maintenance software in particular does not only need to be used for preventive maintenance work. Maintenance teams can also use the software to document repairs, for example. The documentation can build up a knowledge database that can be accessed in the future. In this way, maintenance processes can be further optimised and made more effective. Now one would only have to wait and see and would create the data basis for preventive maintenance.

An example of a prediction that maintenance managers can make by implementing preventive maintenance plans is the prediction of machine component wear. Maintenance managers can monitor the wear of machine components to make predictions about when replacement is necessary before failure occurs. All of this can be thoroughly documented in the software.

By implementing preventive maintenance plans, companies can plan and coordinate the replacement of machine components before a breakdown occurs. This allows them to avoid unnecessary downtime and costs and extend the life of their machines.

– How do I implement such software in my company?

Why cloud software is more flexible than on premise solutions and permanently more cost-saving

Maintenance processes can change and then require rapid adaptation. However, the adaptability of a maintenance software does not depend on whether it is cloud or on-premise based, but on its feature set, structure and configuration options.

The advantage of cloud solutions as opposed to on-premise solutions is that no additional IT infrastructure such as servers and support is needed in the company. This means that the implementation of the software can be done quickly and easily. Only end devices such as workstations, smartphones or tablets are needed to access the software and most of the time this is already available. In addition, cloud software is accessible from anywhere and at any time, which is especially important in times of home offices to stay in touch with colleagues and teams and to collaborate effectively.

Another advantage of cloud maintenance software is that the software is always up to date and updates are carried out automatically. This eliminates the time-consuming update overhead that often occurs with on-premise solutions.

The flexibility of cloud maintenance software means that companies can only pay for the functions they actually need. This allows them to save costs and focus their resources on other important areas. The scalability of cloud maintenance software is also better than on-premise solutions. Companies can quickly and easily increase or reduce the number of licences, depending on their needs. Integrating new applications and functions is also easier and faster.

Overall, cloud maintenance software offers greater flexibility and scalability than on-premise solutions. In addition, it is permanently more cost-saving and offers higher security for the data. Companies should therefore consider the benefits of cloud maintenance software and optimise their maintenance processes.

Does every manufacturing company need maintenance software?

A common argument against the introduction of maintenance software is the question of whether every manufacturing company actually needs such software. For very small companies with only a few machines and one or a few maintenance staff, the use of maintenance software may be overkill. But with cloud technology, even smaller companies can benefit from the advantages of maintenance software.

The ability to test cloud software before buying it is another advantage for smaller companies. They can test the software to see if it suits their needs and if it helps their employees with their work.

Maintenance software in the cloud offers a particularly good opportunity here for small businesses to benefit from the advantages of technology. It does not require additional IT infrastructure and can also be purchased with fewer features to save costs. In this way, small businesses can also enjoy the benefits of maintenance software and optimise their maintenance processes.

By introducing maintenance software, companies of all sizes can make their maintenance processes more efficient and cost-effective. However, the decision to implement maintenance software should always be based on the actual needs of the company. Overall, however, it makes more sense for medium to larger companies to use maintenance software.

Maintenance is not only a topic for manufacturing companies, but also for other industries.

Maintenance processes are not only limited to manufacturing companies, but are also of great importance in other industries such as construction and building technology, healthcare or logistics. These industries often involve the maintenance and repair of buildings, means of transport or medical equipment.

Maintenance processes can also be optimised in these industries through the use of maintenance software. For example, regular maintenance work can be planned and documented to extend the life of buildings or medical equipment and avoid unforeseen breakdowns.

Implementing maintenance software can also help improve efficiency, safety and optimise costs in these industries. By using cloud software, companies in these industries can also benefit from the advantages of technology and take their maintenance processes to a new level.

Maintenance is therefore not just an issue for manufacturing companies, but affects many other industries. The implementation of maintenance software can also lead to an optimisation of processes in these industries and thus increase efficiency and profitability.

Conclusion

In summary, maintenance software is an important factor for manufacturing companies to optimise their maintenance processes. Implementing preventive maintenance plans, monitoring the condition of machines and predicting wear and tear are just a few examples of the functions that maintenance software can offer.

Cloud maintenance software offers advantages such as flexibility, scalability and cost efficiency, as no additional IT infrastructure is required and companies only pay for the functions they actually need. The automation of updates and the constant availability of the software also ensure a high level of security and up-to-dateness.

Although the introduction of maintenance software may be overkill for very small businesses, these companies can also benefit from cloud technology and test the software to see if it meets their needs and if it helps their employees with their work.

However, maintenance is not only an issue for manufacturing companies, but also for other industries such as facility management and logistics. Here, too, the implementation of maintenance software can help create more efficient and cost-effective processes.

Overall, it can be said that maintenance software is an important tool for many companies to optimise their maintenance processes and avoid unnecessary downtime and costs. However, companies should always carefully consider which type of maintenance software best suits their needs and continuously evaluate and adapt the software to achieve the best results.

[This is how we create our content.]